Join our Newsletter receive 🎁

What is MOQ and why can it determine the fate of a collection? A strategic guide for fashion brands

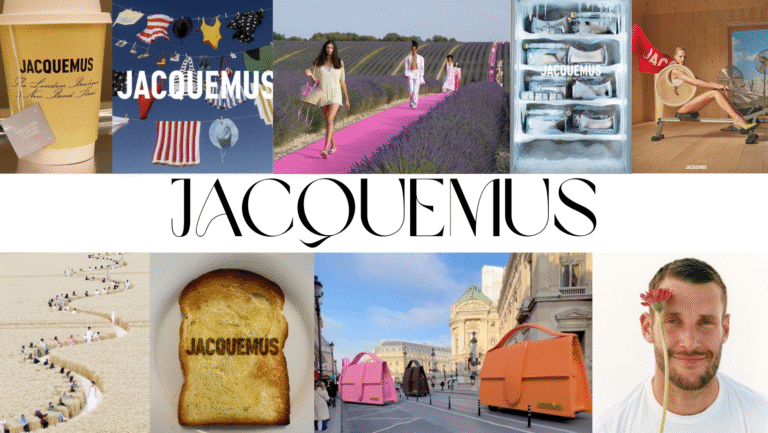

In a world where a designer's creativity and vision are celebrated, there's a concept that can determine the fate of even the most promising collection. MOQ, or Minimum Order Quantity, is a seemingly simple, yet in reality crucial variable in the fashion business. It's not just a number, but a strategic barrier that separates vision from reality, and profitability from bankruptcy. Understanding what MOQ is and how to manage it is absolutely fundamental for any brand seeking to survive and scale its business.

What is MOQ? Definition and Business Realities

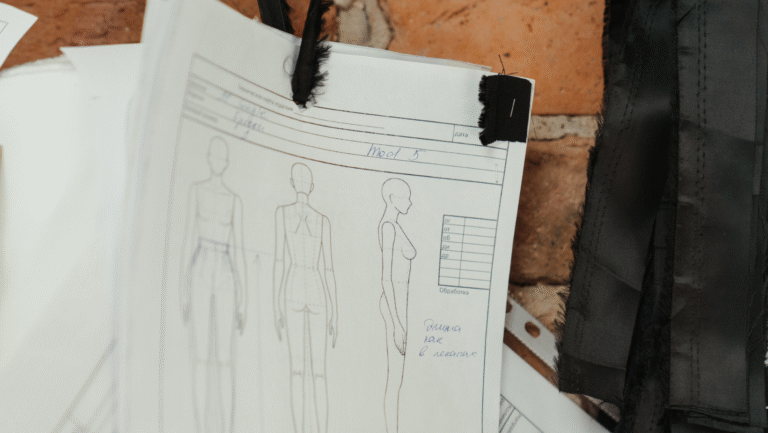

MOQ (Minimum Order Quantity) is the minimum number of units of a given product that a supplier, manufacturer, or factory is willing to produce in a single order. This concept originates from the economics of production and logistics, where every operation, from preparing machinery (so-called setup costs) to purchasing raw materials and transport, has a minimum cost. Manufacturers impose MOQs to ensure profitability and scale efficiency. In other words, producing a single, unique item is unprofitable because fixed costs are spread over too few units.

In fashion, MOQ applies to almost everything:

- Fabrics: Fabric manufacturers often require that you order at least several hundred linear meters of a given fabric.

- Accessories: Buttons, zippers, labels and tags also have their MOQ, which can be up to several thousand pieces.

- Finished products: The sewing room itself will impose a minimum number of pieces per model.

For large fashion houses like Zara or H&M, which operate on a mass scale, MOQ isn't a problem. However, for young, independent brands or start-ups, it's a major obstacle, potentially blocking production from the very beginning.

Why can MOQ decide the fate of a collection? Key reasons

- Financial Trap: A high MOQ forces a young brand to invest more capital in the production phase than it might have anticipated. Having to order 500 meters of expensive fabric for 50 dresses, when the brand only needs 10, leads to capital tied up in unsold raw materials. This is a surefire way to lose financial liquidity.

- Overproduction and waste: In order to meet MOQs, many brands decide to produce more items than they are able to sell. This leads to overproduction and, consequently, the need for discounts and sales, which destroys margins and brand image. In an era of growing environmental awareness, overproduction is also an ethical and image problem.

- Lack of flexibility: High MOQs prevent the brand from responding quickly to changing trends. If one model in the collection does not sell well, the brand cannot simply discontinue production. It is ‘bound’ by a contract for a predetermined, large number of items.

- Barrier to entry for innovation: High MOQs discourage experimentation with new materials, technologies or markets. Manufacturers of innovative fabrics, such as those made from recycled or biomaterials, often impose high MOQs, making it difficult for small brands, which could be their best ambassadors, to implement them.

MOQ Management Strategies: How can small brands beat the system?

Although MOQ seems like an insurmountable obstacle, there are ways to circumvent it or reduce its impact:

- Look for suppliers with low MOQs: Not all suppliers have the same requirements. Small sewing workshops, manufacturers, and local artisans often offer more flexible terms because their businesses are based on a smaller scale and greater personalisation. It is worth taking the time to search.

- Made-to-order approach: Instead of mass production, brands can take orders and only then commission production. This minimises the risk of overproduction and waste, while allowing them to build an exclusive relationship with the customer.

- Collaboration with other brands: Several smaller brands can join forces to place a joint order for fabric. This way, each of them meets the MOQ while paying less.

- Investment in technology: More and more companies offer fabric printing on demand (so-called digital printing on demand), which allows you to order small quantities of material, even a few meters, without having to meet high MOQs.

MOQ is a hard business lesson not taught in design schools. It's a brutal truth about the fashion world, where vision must collide with economics. Those who master this art will not only survive but also build the foundations for lasting success. The rest? Well, the thing about excess inventory is that it's not particularly fashionable.

Sources

- Bouchard, R. (2020). The Business of Fashion: Understanding the Global Industry. Routledge.

- Jackson, K. (2018). Fashion Studies: An Introduction. Bloomsbury Visual Arts.

- Mair, C. (2014). The Fashion Show: History, Spectacle, Body. Bloomsbury Academic.

Subscribe to Fashion Editorial and stay up to date with the world of fashion!

Get the latest news from the world of fashion - trend analysis, exclusive reports and alerts on key industry events.

🎁 Gift for subscribers!.

No spam, only valuable content! We do not share your data with third parties. By subscribing, you agree with our Privacy Policy.

Add your first comment to this post